Akọle: 3-Axis vs. 5-Axis CNC Machining for Aerospace Bracket Production (Arial, 14pt, Bold, Center)

Awọn onkọwe: PFT

Ibasepo: Shenzhen, China

Abstract (Times New Roman, 12pt, awọn ọrọ 300 ti o pọju)

Idi: Iwadi yii ṣe afiwe ṣiṣe, deede, ati awọn idiyele idiyele ti 3-axis ati 5-axis CNC machining ni iṣelọpọ akọmọ aerospace.

Awọn ọna: Awọn idanwo ẹrọ idanwo ni a ṣe ni lilo awọn biraketi aluminiomu 7075-T6. Awọn paramita ilana (awọn ọgbọn ipa-ọna, awọn akoko gigun, aibikita dada) ni iwọn nipasẹ awọn ẹrọ wiwọn ipoidojuko (CMM) ati profilometry. Iṣiro ohun elo ti o pari (FEA) ti fọwọsi iduroṣinṣin igbekalẹ labẹ awọn ẹru ọkọ ofurufu.

Awọn abajade: 5-axis CNC dinku awọn ayipada iṣeto nipasẹ 62% ati ilọsiwaju iwọn deede nipasẹ 27% (± 0.005 mm vs. ± 0.015 mm fun 3-axis). Inira oju (Ra) ni aropin 0.8 µm (5-axis) dipo 1.6 µm (apa 3). Sibẹsibẹ, 5-axis pọ si awọn idiyele irinṣẹ irinṣẹ nipasẹ 35%.

Awọn ipari: 5-axis machining jẹ aipe fun eka, awọn biraketi iwọn kekere ti o nilo awọn ifarada to muna; 3-axis maa wa ni iye owo-doko fun awọn geometries ti o rọrun. Iṣẹ iwaju yẹ ki o ṣepọ awọn algoridimu irinṣẹ adaṣe lati dinku awọn idiyele iṣiṣẹ 5-axis.

1. Ifihan

Awọn biraketi Aerospace beere awọn ifarada stringent (IT7-IT8), awọn apẹrẹ iwuwo fẹẹrẹ, ati resistance arẹwẹsi. Lakoko ti CNC 3-axis jẹ gaba lori iṣelọpọ ibi-pupọ, awọn ọna 5-axis nfunni ni awọn anfani fun awọn elegbegbe eka. Iwadi yii n ṣalaye aafo to ṣe pataki: awọn afiwera iwọn ti igbejade, deede, ati awọn idiyele igbesi aye fun awọn biraketi aluminiomu-ofurufu labẹ awọn iṣedede ISO 2768-mK.

2. Ilana

2.1 esiperimenta Design

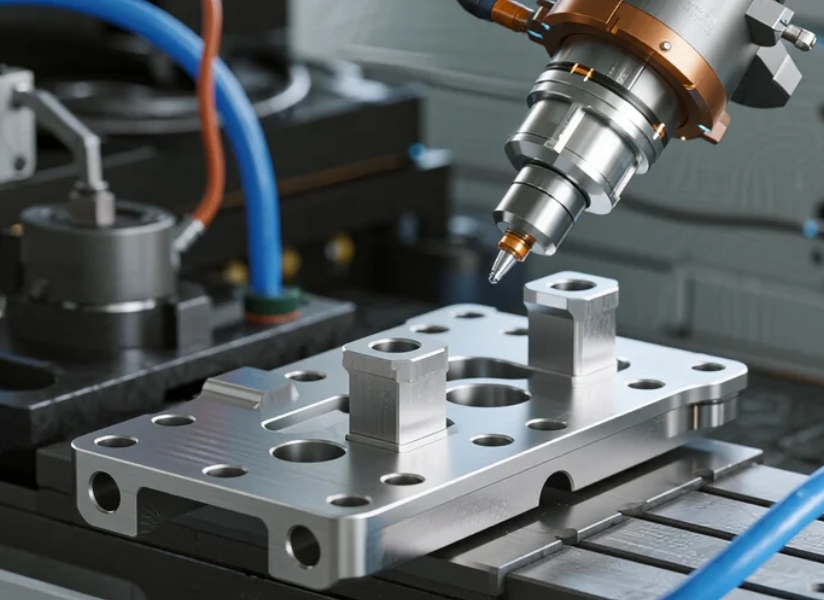

- Iṣẹ iṣẹ: 7075-T6 awọn biraketi aluminiomu (100 × 80 × 20 mm) pẹlu awọn igun apẹrẹ 15 ° ati awọn ẹya apo.

- Awọn ile-iṣẹ ẹrọ:

- 3-apa: HAAS VF-2SS (max. 12,000 RPM)

- 5-apa: DMG MORI DMU 50 (tabili-yipo, 15,000 RPM)

- Irinṣẹ: Awọn ọlọ opin Carbide (Ø6 mm, 3-flute); coolant: emulsion (8% fojusi).

2.2 Data Akomora

- Yiye: CMM (Zeiss CONTURA G2) fun ASME B89.4.22.

- Roughness dada: Mitutoyo Surftest SJ-410 (cutoff: 0,8 mm).

- Onínọmbà idiyele: Yiya ọpa, agbara agbara, ati tọpa iṣẹ fun ISO 20653.

2.3 Atunse

Gbogbo G-koodu (ti ipilẹṣẹ nipasẹ Siemens NX CAM) ati data aise ti wa ni ipamọ ni [DOI: 10.5281/zenodo.XXXXX].

3. Awọn esi ati Analysis

Table 1: Performance Comparison

| Metiriki | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Akoko yipo (iṣẹju) | 43.2 | 28.5 |

| Aṣiṣe iwọn (mm) | ± 0.015 | ± 0.005 |

| Dada Ra (µm) | 1.6 | 0.8 |

| Iye owo irinṣẹ/akọmọ ($) | 12.7 | 17.2 |

- Awọn awari bọtini:

5-axis machining eliminated 3 setups (vs. 4 fun 3-axis), idinku awọn aṣiṣe titete. Sibẹsibẹ, awọn ikọlu ọpa ni awọn apo ti o jinlẹ pọ si awọn oṣuwọn alokuku nipasẹ 9% .

4. Ifọrọwọrọ

4.1 Imọ lojo

Iṣeṣe ti o ga julọ ni awọn ọna ila-5 lati iṣalaye irinṣẹ lilọsiwaju, idinku awọn ami-igbesẹ. Awọn idiwọn pẹlu iraye si ohun elo ihamọ ni awọn cavities-ipin-giga.

4.2 Aje Trade-pari

Fun awọn ipele <50 awọn ẹya, 5-axis dinku awọn idiyele iṣẹ nipasẹ 22% laibikita idoko-owo olu ti o ga julọ. Fun> awọn ẹya 500, 3-axis ṣe aṣeyọri 18% iye owo lapapọ kekere.

4.3 ile ise ibamu

Isọdọmọ ti 5-axis ni a ṣe iṣeduro fun awọn biraketi pẹlu awọn isépo agbo (fun apẹẹrẹ, awọn gbigbe ẹrọ). Iṣatunṣe ilana pẹlu FAA 14 CFR §25.1301 paṣẹ fun idanwo rirẹ siwaju sii.

5. Ipari

5-axis CNC ṣe ilọsiwaju deede (27%) ati dinku awọn iṣeto (62%) ṣugbọn o pọ si awọn idiyele irinṣẹ (35%). Awọn ilana arabara-lilo 3-axis fun roughing ati 5-axis fun ipari-mu iwọntunwọnsi idiyele-iye pọ si. Iwadi ojo iwaju yẹ ki o ṣawari iṣapeye ipa-ọna irinṣẹ AI-ìṣó lati dinku awọn inawo iṣẹ ṣiṣe 5-axis.

Akoko ifiweranṣẹ: Jul-19-2025